Electric Hydraulics: Revolutionizing the Mobile Hydraulics Industry

Leave a Comment

The Future of Hydraulics is Electrifying

In recent years, the mobile hydraulics industry has been revolutionized by the development and proliferation of electric hydraulic systems. Among other inherent benefits, electric hydraulic systems could also be dramatically more energy efficient compared to traditional hydraulic systems.

How is this possible? Unlike traditional hydraulic systems, electric hydraulic motor-pump units only operate when flow and pressure are required to perform the working task at hand.

When there is no flow or pressure required, the electric hydraulic motor-pump unit switches to zero energy-mode, saving the consumption of energy and increasing the system’s efficiency. This is what we call energy efficiency.

Energy Efficiency through Electric Hydraulics

Energy efficiency, put simply, is when less energy is needed for a system to get the job done. This can be achieved by lowering the amount of energy consumed to accomplish an equivalent output (e.g. halt of use when not in operation).

Think about some of the newer car models in the market today.

Some higher-end models shut down every time the car stops at a stop light. Since the car is in idle at that stop light, why would the car continue to place tension and wear the performing components when they’re not performing their sole duty: driving?

This way of thinking is slowly creeping into hydraulics too. Experts are now looking at ways to incorporate these (and other) types of electric energy to power hydraulic machines. This is called electric hydraulics.

Electric Hydraulic Advantages

Electric hydraulic systems have some major advantages over their traditional hydraulic counterparts. The key advantages of electro-hydraulic motor pump units are:

- Up to 70% more efficient than standard hydraulic counterparts

- CO2 reduction = less fluid being used in the system

- Component lifespan increased, especially with bearings and seals

- Ability to control direction & amount of hydraulic flow by controlling direction/speed of the electric motor.

- Injection molding machine systems eliminate the need for directional and proportional valves in the motion axis.

- Fewer, less complicated components also simplifies troubleshooting.

- Quieter run times, reducing noise decibel readings

- Save space and reduce weight with lighter, more compact electric systems

- Integrated electrohydraulic packages are now available. These packages include an electric motor, controller, and hydraulic pump combined into one compact unit to lower total cost of ownership.

With the rising trend of electric drive vehicles and utilizing efficient energy throughputs, there is now a need to reduce power consumption and extend the battery life through increased hydraulic efficiency. How do we capitalize on saving energy and becoming more efficient in electric hydraulic systems?

The answer: minimize the pressure drop

Electric Drive Savings Through Pressure Drop Reduction

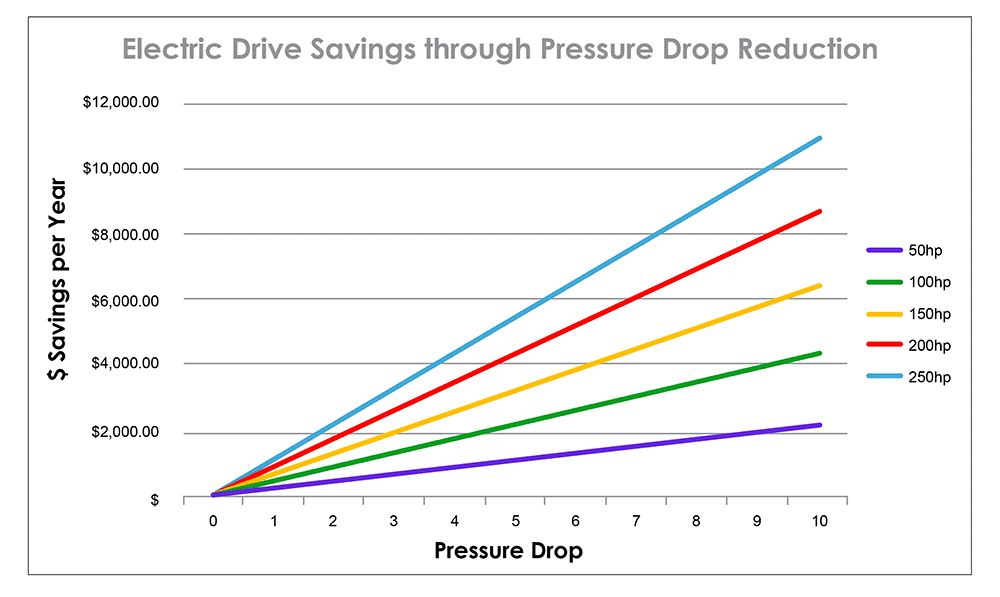

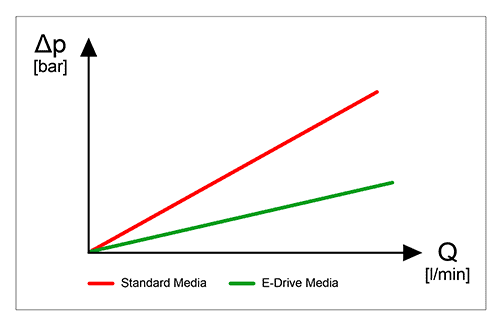

All energy has a price, and wasting it means wasting meaningful dollars. It is desirable to have as much energy that is inputted into a system available to do useful work. In hydraulic systems, we tend to look at differential pressure across the entire system. Differential Pressure describes the loss of energy available in a hydraulic system—however, the energy is not lost, but converted into thermal energy, which is unavailable to perform useful work.

For example, a small pressure drop effects high horsepower systems, as the pump/motor group must make up for that loss of energy and operate much harder, costing more money and shortening component life. Take a look at the figure below to see an example of how much money can be saved by lowering the pressure drop by a few psi:

So how do we lower the overall pressure drop in an electric hydraulic system? That is where Schroeder’s Electric Drive media can help.

Schroeder’s Electric Drive Media

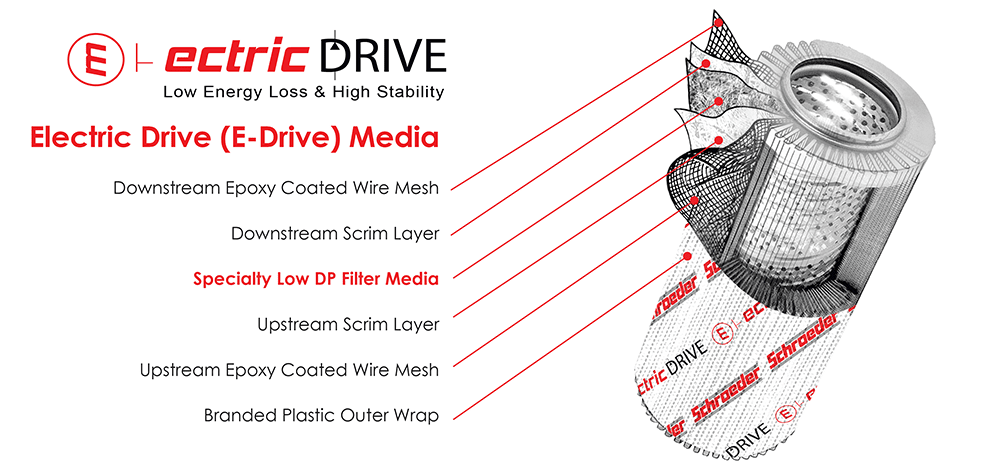

The use of Schroeder’s GREEN, Electric Drive (E-Drive) Media filtration technology guarantees safe and reliable equipment operation, all-while conserving the use of energy.

Part of Schroeder’s Energy Saver initiative, filter elements made using the all-new E-Drive Media are characterized by a low pressure drop, making them suitable for low energy requirements compared to conventional hydraulic elements under the same ambient conditions.

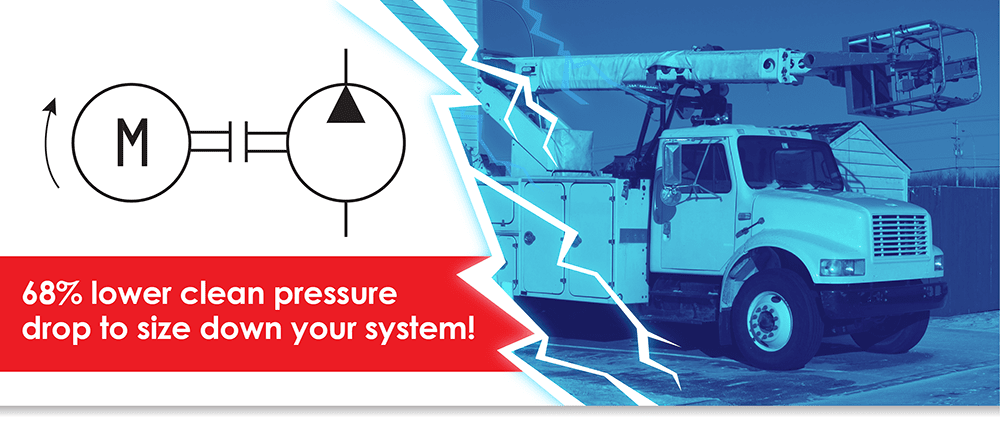

In certain applications, the E-Drive Media can lower the pressure drop to a point where consumers may be able to size down their horsepower requirements on their current motor and save even more overall!

E-Drive filter elements are made using an all-new specialty formulated, high efficiency, low differential pressure media and are the perfect choice for use in electric hydraulic drive motor-pump units. Use them for conserving energy bills and wherever high viscosity fluids are employed – especially at low temperatures that produce a cold start behavior.

Let’s see how our 10-micron Electric Drive media element compares to the typical synthetic microglass media available on the market today.

Technical Specs (evaluated in K-sized element):

| Media Type | β200 [µm(c)] | Pressure Drop Factor [psid/gpm] |

| E-Drive Media (10 µ) | 10.2 | 0.050 |

| Typical Synthetic Media (10 µ) | 10.6 | 0.156 |

- Element Collapse Rating: 145 psid (10 bar)

- Temperature Range: -22°F to 212°F (-30°C to 100°C)

- Flow Direction: Outside to Inside

E-Drive Media is currently rated for 10-micron filtration, with other micron options available in the near future.

What Can E-Drive Media Do For You?

To see if Schroeder’s Energy Saving Initiative E-Drive Media can be the right solution for your electric hydraulic systems, email us at sisales@schroederindustries.com or leave a comment in the blog post below.

E-Drive Media is part of Schroeder Industries’ 2030 Initiative, a suite of filtration solutions and technology proven to support carbon neutrality goals. Learn more about how Schroeder Industries and sustainability go hand in hand!

Achieve Better Machine Performance Through Fuel Filtration

Leave a Comment

A Look into the World of Fuel Filtration

Schroeder Industries’ wide offering of fuel filtration solutions represents the cutting edge in innovative and advanced fuel filtration technology.

Our range of products are designed specifically for fuel filtration applications. This includes bulk storage, mobile equipment prefiltration, alternative fuels, and fuel contamination monitoring. All are engineered to address the problems with modern fuels in a compact, reliable, and cost-effective way.

At Schroeder Industries, we apply innovative technology to meet the global needs of fuel cleanliness. We work to provide a wide selection of light weight, and compact solutions.

Our product range includes fuel filters, filtration systems, and condition monitoring equipment for all-around diesel protection. Schroeder Industries has our customers covered from production to consumption.

Fuel cleanliness is a main factor in making sure diesel-powered machinery and diesel engines are operating at their highest performance.

To put it simply, the most important thing we can do, is make sure your fuel is free of any contaminants. This can include water, particulates, fungi, etc. Our products are designed to remove these contaminants.

Contamination can cause microbial growth, which can cause destruction in your fuel systems. This can lead to field failure and can allow bacteria to spread in your system.

Fortunately, with Schroeder Industries, our filters can get these destructive contaminants out of your fuel. Bringing them up to exceptional cleanliness levels.

With our fuel diagnostic technology, you can take a preventative approach and know when exactly your fuel may need extra support.

Our Fuel Filtration Technology and the Environment

We recognize the world is seeking more environmentally sound ways of creating equipment that uses more efficient technologies and systems.

We are always looking for ways to keep this global movement in the focus of our development. This includes making strides in creating more energy efficient fuel filtration technology.

Many of the global equipment manufacturers are making advancements in the electrification of mechanical or hydraulic systems and equipment. This doesn’t get rid of the need for diesel fuel or alternative fuels, but underscores the importance of better fuel filtration.

Modern fuels are made to adhere to the standards addressing emissions, equipment reliability, safety, and storage. Therefore, our fuel filtration technology follows the same standards. It is of high importance for us to know the problems faced as fuels continue to change.

Engines are becoming smaller to make room for the electrical components, wiring, and storage. It is crucial to provide the highest performance filtration in a compact and lightweight package.

However, this does not eliminate the need for bulk diesel, or alternative fuel. This makes the need for your pristine fuel quality even more essential.

Schroeder Industries also understands the importance of being environmentally friendly.

We use advanced technologies to minimize the energy needed to clean and condition fuel. This encourages the reclamation of fuels that would normally be disposed of. Doing this can result in reduced waste and an overall reduction in emissions, helping to accomplish a cleaner world.

Schroeder Industries is ISO 9001 certified and members in good standing with PEI. Both organizations help fulfill our dedication to making sure all of our customer’s fuel quality is outstanding. Our team stays up to date on the guidelines from the International Organization for Standardization (ISO) 4406 and industry trends from PEI.

Watch on YouTube “Fuel Filtration” Playlist.

Embrace Patented Technology with our Hydraulic Tank Accessories

Leave a Comment

What Are Hydraulic Tank Accessories?

Schroeder Industries offers a complete range of hydraulic fluid tank accessories, subsystems, and individual components such as breather filters.

The Hydraulic Tank Accessories Product Categories focus on providing the components that make up the entire hydraulic reservoir.

Each component on the reservoir performs a key role for fluid care and hydraulic motors.

We not only produce tank-mounted return filters, we also manufacture and supply every component needed to make a reservoir even more valuable to the overall fluid system.

We have:

- Air breathers (both synthetic media and silica gel options)

- Strainers

- Sight gauges

- Reservoirs

- Component level products such as types of level gauges/liquid level gauges, electrical and visual indicators are also included in this product line

*All available for private labeling making Schroeder Industries your one-stop shop private label manufacturer (see below)!

Why Should I Use Schroeder Hydraulic Tank Accessories?

Schroeder Hydraulic Tank Accessories serve many purposes. Our primary goal is to keep fluids under high pressure as clean as possible.

We use patented technology in an attempt to secure the national brand product in the market.

Our customers will tell you that we have the best:

With Hydraulic Tank Accessories, it is important for them to seamlessly integrate with your equipment. In addition to the products mentioned above, we also make hydraulic adapters and hydraulic connectors to make incorporating our accessories simple.

Customization at Schroeder doesn’t stop with our filter products.

With every aspect of the hydraulic circuit covered, we have an unrivaled ability to create custom solutions to fit your exact needs. Whether it be a sizing requirement on a hydraulic pump or a specific location for an adapter. Schroeder Industries has a plan for you.

Markets Our Accessories Currently Serve

We Offer Private Labeling on Products

Private labeling is a significant feature Schroeder offers for multiple products. This includes accessories.

Private label goods are perfect for companies that already use Schroeder Industries products within their equipment. We have the option to private label brand all of the components mentioned above to represent your brand.

Ask about our interactive forms to screen-print, laser, or paint any and all information you require on your product. Our forms allows our customers to design the label exactly how they want it, so we get the best outcome.

Flexibility options include:

- The location of your logo

- How you’ll send the artwork

- Custom markings

- Barcodes

At Schroeder Industries, we’re committed to finding the perfect results for you and your company. Reach out today for a Schroeder Hydraulic Accessories solution!

Watch on YouTube “Tank Optimization | Complete Package Solution”.

Request a Quote – Hydraulic Tank Accessories

Request for Quote

Protect Your Hydraulic System with Remarkable Contamination Control

Leave a Comment

Fluid Contamination Control: What You Need to Know

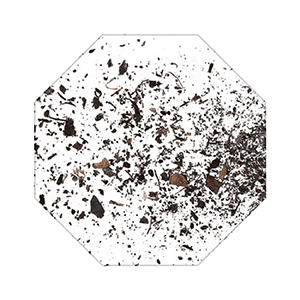

Over 70% of all system failures are caused by contaminants in the fluid. Even when no immediate failures are apparent, high contamination levels can be present and sharply decrease hydraulic controls in the blink of an eye.

Contamination is defined as any substance foreign to the manufacturing equipment and damaging to its performance. If not controlled, contaminated hydraulic fluid can impact hydraulic system efficiency, reduce the lifespan of machine components, or even cause a catastrophic failure of hydraulic equipment, among other issues. Proper preventative measures, namely filtration, are critical.

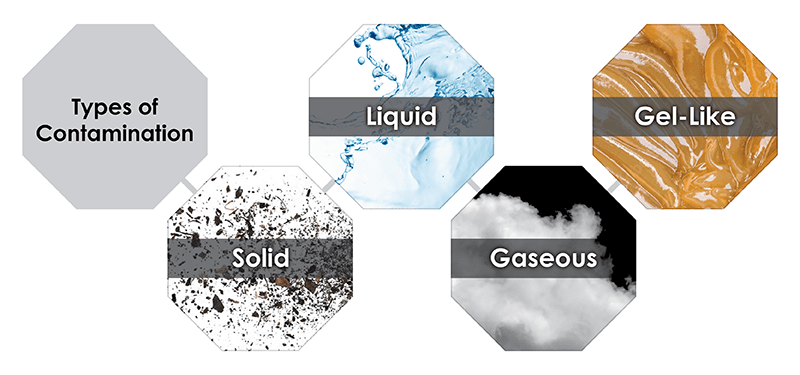

There are four primary types of fluid contamination, each of which contribute to machine and component wear in their own ways. Each type of contamination can have a cascading effect which contributes to the other types.

Contamination can also act as a catalyst to accelerate oxidation of the fluid and spur the chemical breakdown of its constituents.

Watch on YouTube “Fluid Contamination Control: What You Need To Know”.

What is Hydraulic and Lube Filtration?

Hydraulic and Lube Filtration is the perfect candidate for combatting issues with contaminates.

It will provide one of the only value statements you will ever need.

Schroeder Industries offers a full division of Hydraulic and Lube Filtration. With 75 years of manufacturing experience, there’s a solution for every facet of a hydraulic system, including:

- Top / Base Ported Filtration

- Manifold Mounted Filter Kits

- Hydraulic Tank Filters (In-Tank / Tank Top)

- Servo Protection Filters

- Tank-Mounted Suction Filters

- And more!

By utilizing filter technology for your operating fluid, it will remove many of the contaminates mentioned above and extend the life of the system components (also mentioned above).

The filtration process helps remove contamination from oil systems and conditions the fluid on a continuous basis. It also ensures the oil viscosity properties remain constant per the desired temperature ranges.

Interested in protecting your equipment with hydraulic filtration products from Schroeder Industries? Our Distributor Locator can help connect you with a member of our expansive distributor network.

Watch on YouTube “The 7 Steps to Choosing the Correct Filtration”.

Schroeder Industries’ offers Hydraulic and Lube filter assembly types up to 6,500 psi (448 bar).

Using fluid technology, our hydraulic filter housings are continuously tested using the latest ISO (International Organization for Standardization) and NFPA (National Fluid Power Association) test procedures in our Fluid Care Center (FCC). Extensive testing is conducted to verify rated fatigue and burst pressures and to ensure compatibility with various mineral-based fluids.

Request a Quote – Hydraulic Filtration

Request for Quote

Trusting the Experts on Process Filtration Results in Reliability

Leave a Comment

What is Process Filtration?

Process filtration is a major focal point of what we do at Schroeder Industries.

The filtration process is commonly used to remove contamination and solid particles from gas-solid or liquid-solid process streams.

Additionally, there are filtration solutions to improve one’s operating water quality. This includes:

- Process water

- Waste water

- River water

- Cooling towers

- Backwash

- Industrial gases

- Low-viscosity fluids

- And all other types of oil, fuel, water, and compressed gases

We’ve even coined the phrase “if it flows, it’s probably Schroeder”.

Trust the Experts of Process Filtration

Proper filtration in treatment processes such as process water, wastewater discharge, or reuse is critical.

Moving liquids or gases from somewhere like a refinery, food/beverage, steel, automotive, pulp and paper or oil produced water application requires pre-filtration due to high amounts of suspended solids in these typical applications.

In fact, there are usually several filtration and treatment steps in these applications to ensure that the treated water meets the required discharge or reuse standard.

In addition, filtration in treatment schemes ensures reduced operating cost on downstream polishing treatment systems.

Schroeder Industries Focuses on Your Process, Delivery Reliability and Improvements

Schroeder Industries will optimize your filtration solution based on the specific characteristics of your system, including the water source, specific application, and downstream equipment.

Poor filtration can cause a degradation of your final product or failure of downstream equipment. This can cost hundreds of thousands, or even millions of dollars in downtime or wasted product.

Schroeder Industries is here to partner with you to ensure reduced maintenance and high quality filtration designed specifically for your application.

The most important aspects of the application of filtration process include:

- Performance

- Efficiency

- System parameters

- Stable emulsions

- Water intake

- Economic impact

For instance, a very important step in a membrane treatment plant in the United States is the pretreatment of fluid to remove large particulate and biologicals.

If unmanaged, poor prefiltration can result in:

- Increased maintenance costs

- Increased energy consumption

- Damaged components (like a pump or heat exchanger)

- Reduced service times

But why Schroeder?

At Schroeder Industries, our 75 years of industrial application of filtration has lead us to offering just three (3) common design-types of process filters:

- Backflush, Self Cleaning Filters/Strainers (automatic and manual) covering a wide range of flow and filtration ratings.

- The elements in all backflush filters are reusable and economically sound.

- Backflush filters offer low maintenance requirement and low operating costs.

- This includes our line of backwash, automatic self cleaning water filters and auto strainer filters.

- Bag Filter Systems come in multiple standard sizes of 1, 2, 3, and 4.

- These are most suitable for coarse and fine filtration.

- This includes our line of single, duplex and oil absorbing bag housing and element solutions.

- Cartridge Filter Systems are elements that apply depth filtration.

- Depth filtration increases dirt holding capacity while offering efficient filtration.

- These are also suitable for fine filtration.

- This includes our line of self cleaning cartridge filters, basket strainers, and more.

Learn how to open ro filter candle – Watch on YouTube “PLFx Series | Process Inline Filter”.

We also own exclusive partnerships to help us be your one-stop partner in filtration.

We have partnerships with:

- nuove energie

- LG Chem

- And more!

It is our experience that your project will flourish with any one of the options listed above.

The option always lives to choose one, proceed, and move forward on the project at hand.

What if I have needs not satisfied by the options listed above?

If we later determine that one of the aforementioned options does not quite meet the goals you have set in place, we also specialize as an engineering firm. Our in-house team has the ability to look at your operational design and personalize a process filtration solution fit for your individual needs.

This may even include taking one of our existing solutions and retrofitting it to your specific needs.

The Schroeder Guarantee

Schroeder ensures protection of product and equipment, no matter what the project. To do this, it is important to perform selective filtering of solids from gas and liquid process streams. Poor filtering can cause a degradation of your final product or failure of equipment. This can cause hundreds of thousands or millions of dollars in downtime or wasted product.

An infinite amount of applications and gases/liquids exist and Schroeder has the expertise to determine your optimal filtration needs. Schroeder has the optimized filtration solution based on your media, economics, permits, filtration goals, etc. This can include industrial processes, mining food and beverage, drinking water and wastewater.

Watch on YouTube “Process Technology | Water Filtration Systems”.

In this vast world there are no two applications that are exactly alike. Schroeder Process Division has the experience and expertise to provide you with personalized answers and solutions. From low viscosity water, emulsions and machine coolants to heavy fuels to compressed gas applications – Schroeder is your filter expert!

About us – Schroeder Industries – A US Company

Schroeder Industries (celebrating 75 years in 2021) is a US Corporation that started as a mining equipment manufacturer and reseller in 1946. Since then, the company has evolved to be a leading firm in the development and production of fluid power conditioning equipment. Schroeder designs solutions for both OEM and MRO, Industrial and Mobile Equipment. From hydraulic fluids and low-viscosity fluids to process water and fuels. A partnership with Schroeder guarantees innovative products, processes, and solutions to improve performance and efficiency in your equipment.

Schroeder’s Powerful Technology for Oil Conditioning

Leave a Comment

What is a Fluid Filtration System?

A fluid filtration system is exactly what it sounds like. These systems are designed to ensure the quality of your fluid is excellent.

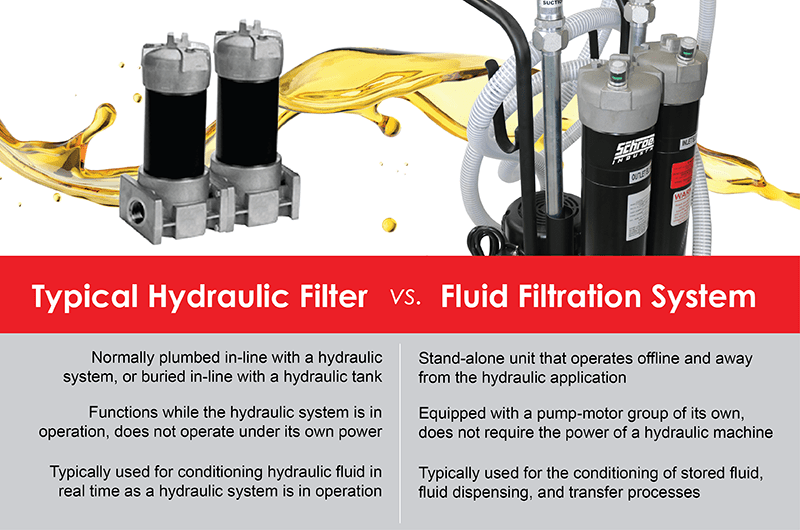

With a typical hydraulic application, the hydraulic filter is normally plumbed in-line with the system (or buried in-line with a hydraulic tank) and serves as an oil conditioning unit when the system is in operation.

A fluid filtration system, or oil conditioning unit, is a stand-alone unit that operates offline and away from the hydraulic application. Often times in the form of a hydraulic filter cart, it is not to replace any piece of equipment, but to enhance the maintenance team.

Equipped with a pump-motor group of its own, these do not require the power of a hydraulic machine. They are their own system.

Oil conditioning units are typically used for the conditioning of stored fluid, fluid dispensing applications and transferring processes. It is basically summed up that everywhere the fluid is not flowing through a system, it should be accompanied by a hydraulic filter cart.

What is meant by “Oil Conditioning”?

With the turn to tighter tolerances in today’s hydraulic critical assets systems, line conditioning equipment is critical.

What do we mean when we say “Oil Conditioning”?

Oil Conditioning is using fluid conditioning products, such as offline oil filtration and dehydration systems, to remove contaminates and increase the moisture removal rate in your hydraulic fluid. Removal of the contaminates and the total moisture allows the system to operate to its fullest potential. Contamination is a leading cause of hydraulic repairs and replacements, and accounts for 70 to 90% of wear and failure.

Whether your machine is new or many years old, the cleaner the oil, the better the operating condition.

When contaminants enter a hydraulic system, the manufacturer’s advertised performance of that machine is not achieved.

This adds an increased strain on components such as turbine oil filters, other line conditioning equipment, and more.

Today’s oil conditioning units have seen a shift from “Reactionary” (fix it when it breaks) to “Preventative” (fix it before it breaks), and even “Predictive” (schedule downtime to perform maintenance).

What are Diagnostics Tools?

Similar to a diagnostic OBD II scanner you have for your car, diagnostic tools are the equipment that can recognize and support a “Preventative” maintenance plan.

Bring that into the world of hydraulics and you get equipment similar to the OBD scanner mentioned above.

Only this time, these diagnostics read and report in the form of mineral oil cleanliness.

Watch on YouTube “Diagnostics (IoT)” Playlist.

What do Diagnostics Tools have to do with Oil Conditioning Units?

When you pair the elite technology found in today’s oil conditioning units with the new-age of the Internet of Things (IoT) technology in most diagnostic tools on the market today, you really step into the future in a real effort of streamlining tedious oil sampling/reporting tasks in a complete system.

The two technologies together are what we like to call proactive “Contamination Control” – taking ownership and managing the fluids you pump into your hydraulic systems day-in and day-out.

“Contamination Control” pertains to the ISO clean analysis and optimization of processes with regard to the cleanliness of components, systems and the purity of the fluids used.

“Contamination Control” is also an important part of operating and maintaining hydraulic systems, like a hydraulic filter cart.

How can Schroeder Industries help?

It starts with the identification and measurement of the different forms of contamination.

Our line of condition monitoring products include both in-line and offline sensors to measure contamination and/or total moisture levels of the hydraulic system.

If the contamination levels are at a certain degree, our end users have seen dramatically frequent equipment failure.

If monitoring is the first step, fluid conditioning products would be the second.

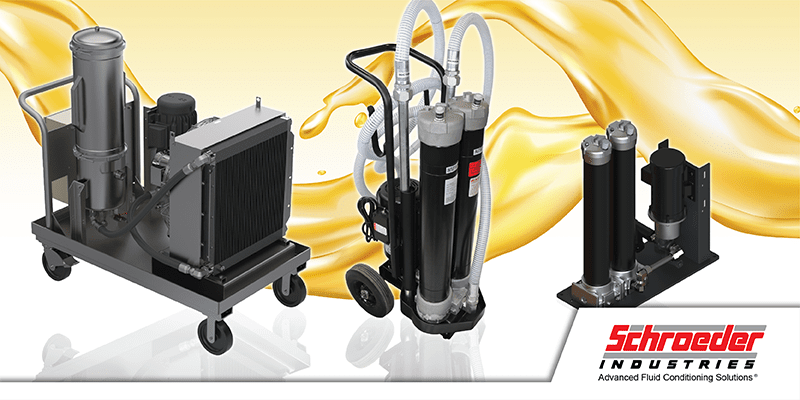

Our line of offline, mobile fluid handling carts are perfect for removing contaminants and increasing overall moisture removal rate from various types of hydraulic fluids.

Oil conditioning units include both mobile fluid handling carts with or without contamination monitoring units, stationary fluid conditioning products from 1.3 gpm flow rates to customizable kidney loop systems up to 140 gpm.

Each of our hydraulic filtration systems are equipped with high efficiency elements to remove solid particulates and/or free water quickly and efficiently.

Our dewatering units, both hydraulic vacuum oil dehydration and mass transfer systems, can remove both free and dissolved water from hydraulic fluids for any reservoir size at various flow rates.

Watch on YouTube “Filter Systems” Playlist.

By implementing fluid condition monitoring equipment, in conjunction with the appropriate filtration equipment, a major portion of particulate contamination introduced during manufacturing and assembly can be effectively and efficiently removed.

The result will be improved fluid condition, extended life expectancy of fluid and equipment resulting in significant cost savings, and peace of mind that your systems are functioning appropriately and efficiently.

Request a Quote – Fluid Filtration System

Please include the FS & Diagnostic Tools Fluid Condition and Condition Monitoring Project Application Questionnaire as an attachment below.

Request for Quote

Make Sure Your Equipment is Secure with Schroeder Element Technology

Leave a Comment

What is a Hydraulic Filter Element?

Filter elements are the heart and soul of every high pressure fluid power system. The main job of hydraulic filtration is to clean hydraulic fluid. This is achieved by removing impurities and contaminants in the system.

They are also used to ensure that contaminants do not interfere with the hydraulic machine’s main operating functionality. Such as maximizing efficiency and offering low energy consumption.

When a hydraulic oil filter removes those contaminants from a hydraulic system, an increase in the fluid’s cleanliness level is achieved. This results in the reduction of machine downtime and maintenance costs. A hydraulic oil filter also increases hydraulic fluid and component life, such as hydraulic pumps, hydraulic motors, etc..

Why Schroeder Filters?

At Schroeder Industries, our elements:

- Remove impurities and contaminants

- Meet required cleanliness levels

- Preserve energy on system components

- Maximize overall efficiency.

Schroeder Filter Media options that can help achieve your hydraulic fluid cleanliness and system efficiency goals. With numerous micron ratings and media options, there is a solution for you!

Use of Non-Schroeder Elements in Schroeder Filter Housings:

Due to the possibility of a fit, form, and function error, Schroeder Industries does not recommend nor

guarantee that a non-Schroeder filter element can be used properly in a standard Schroeder filter housing. Other businesses have filter elements that are not controlled by Schroeder, which may cause decreased performance and system downtime.

Potential Effects of Using Non-Schroeder Elements:

- Increased and Uncontrolled ISO Counts

- Lower Beta Efficiencies

- Uncontrolled Contamination Introduced in System

- Lower Dirt Holding Capacities

- Dissimilar Component Material from Original Specifications

- Material Issues Mixing with Hydraulic Fluid

- Premature System Component Failures

- Uncontrolled System Downtime

How can I tell if my hydraulic filter is working?

Genuinely, a filter element’s performance can be measured. Such factors to watch include:

- Beta Efficiency – how well it can remove contamination through fluid conditioning

- Beta Stability – how well it can maintain its efficiency throughout its life

- Dirt Holding Capacity (DHC) – how much contamination it can hold

- Lower Pressure Drop – how restricting it is on the hydraulic system

Resources

Watch our YouTube “Filter Elements” Playlist for more product information: